-

Product 01

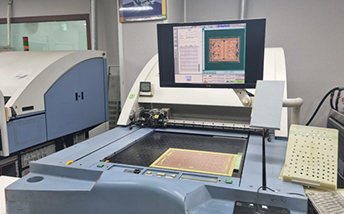

Product 01A.O.I(Auto Optical inspection)

Auto Optical Inspection: Equipment that inspects open, short, slit, pinhole, copper foil residue, foreign substances, etc. of circuits that may occur in internal and external image processes

-

Product 02

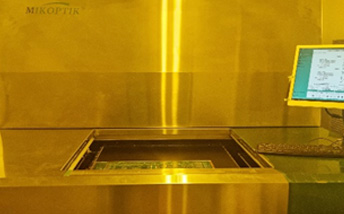

Product 02L.D.I(Laser Direct Image)

Equipment that forms a circuit by exposing CAM Data directly to the PCB without a photomask film.

Microcircuits are realized by directly exposing to PCBs without using mask films. -

Product 03

Product 03HOT PRESS

It is a press equipment that stacks the inner layer substrate, the prepreg, and the copper foil for forming the outer layer circuit according to the design specifications. It is bonded by pressurization and heating to form a multilayer substrate

-

Product 04

Product 04PCB inkjet Printer

Equipment that prints typeset by applying ink directly to products that have been solder mask printed based on CAM data without the need for photomask film and silk screen

-

Product 05

Product 05CNC Drill

Equipment that processes holes on the working panel by CNC (Computer Numerical Control) method using data edited based on customer hole information

-

Product 06

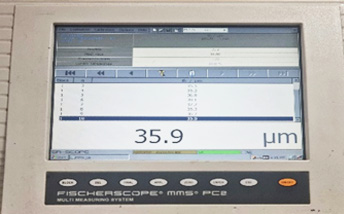

Product 06Plating Thickness Measuring Equipment

Equipment that measures thickness after copper plating on the surface of the product

-

Product 07

Product 07Laser Drill

Equipment that processes Laser VIA Holes on the Working Panel by CNC (Computer Numerical Control) method using data edited based on customer hole information

-

Product 08

Product 08B.B.T(Bar Board Test)

Equipment that inspects basic electrical performance such as electrical defects on circuits, i.e. open & short, insulation gap violations, etc., after PCB machining is completed